Aftermarket Auto Parts Maker Sees Booming Sales Ahead

Mar 11, 2003 Ι Industry In-Focus Ι Auto Parts and Accessories Ι By Quincy, CENS

Non-original equipment (OE) auto parts aimed at the aftermarket have steadily been gaining popularity around the world—especially in the United States—and manufacturers in Taiwan are having to expand their production capacity to meet the booming demand.

Local manufacturers in the line point out that more car owners than ever are now willing to use non-OE parts in their repairs. Statistics compiled by the Insurance Research Committee (IRC) of the U.S. show that the acceptance ratio for such parts in that country now stands at 52%, more than double the 2000 figure of 25%.

An even higher 57% of American consumers are willing to use such parts if they bear marks showing ISO9000, Certified Automotive Parts Association (CAPA), or Manufacturers' Qualification and Validation Program (MQVP) quality approval. This indicates that non-OE parts have become the mainstay of the aftermarket in North America.

OE replacement parts are often distributed through auto manufacturers' own service channels and sold under their own brands, while non-OE aftermarket parts, which have the same specifications as their OE counterparts, are often sold without certification or authorization by the automakers.

Several major producers in Taiwan predict that sales of their aftermarket auto parts will expand by about 20% annually in 2003 and the next several years, due largely to the fact that the number of older cars on the world's streets and highways is growing rapidly because of the weak global economy and the improved durability of late-model cars.

Reflecting the change in consumer habits as well as cost concerns (aftermarket parts cost only about 60% to 80% as much as OE counterparts), more and more insurance companies are using the prices of aftermarket parts in calculating compensation payouts. Farmers and Nationwide, the third- and fourth-largest U.S. insurance firms, have already taken this action, and State Farm, the biggest, is expected to shortly follow suit. This is expected to help boost the American market for aftermarket parts by 20% to 40% this year.

The acceptance of aftermarket parts is also benefiting from the differential-premium system offered by American insurance firms, which allows policyholders to pay lower premiums if they agree to the use of aftermarket parts to repair their cars.

Expanding Production

In response to the burgeoning market, local manufacturers are expanding their production both in Taiwan and overseas. They are also diversifying their product lines with the aim of attracting more one-stop shoppers.

One example of this trend is provided by Gordon Auto Body Parts Co., a leading local supplier of aftermarket sheet-metal body parts, which claims that it has invested over NT$100 million (US$2.9 million at NT$34.8:US$1) to expand production at its second Taiwan plant by installing two new stamping lines. When this project is completed in the second quarter of this year, it will give the company an annual capacity of 1.5 million sheet-metal parts.

Gordon also says that it spends an average of NT$400 million to NT$500 million (US$11.5-14.4 million) a year on die development. It plans to develop 50 additional dies this year, bringing the total to over 500.

The company's chairman, Lee Mao-yuan, is highly confident in his firm's prospects. "We expect to lengthen our lead over our major domestic rivals this year," he explains, "thanks to our expanded production capacity, our new dies, and the flood of orders coming in from our customers—especially those in the U.S. market."

Two specific factors, in addition to those noted above, will help the company meet its sales projections this year. One is that Gordon's biggest American buyer, Keystone Automotive Industries, has been aggressively acquiring major auto-parts distributors in the North American market. Over the past 12 months alone, the company has acquired Advance Bumper, Springfield Body Parts, and Missouri, aiming at quickly adding to market share. Keystone has announced plans for a series of new acquisitions this year, which will also be good news for Gordon's sales in America.

The other factor, Lee explains, is the reduction of Gordon's production costs because booming demand has heightened its die-utilization ratio. Also, of course, the company is expected to end its long-term capacity shortage through the above-mentioned expansion at its second Taiwan plant as well as through the strengthening of cooperative ties with satellite plants.

Advantage of Experience

In the face of rising competition from a group of newcomers to the line, Lee comments, Gordon's competitive edge lies mainly in its long-term manufacturing experience and its dedication to the continual development of more advanced production technology. "This is why our company has been able to stand firm amidst the bloody competition in the past," he explains.

In addition, Lee says, the company's strategy of developing comprehensive die series instead of one-offs makes it an ideal supplier of one-stop-shopping services.

Gordon is not going the way of many other auto-parts makers, who according to Lee aim at becoming OE suppliers because of the higher profit margins this makes possible. In fact, he explains, "Aftermarket-parts makers can use much more flexible pricing strategies or tactics and gain even better profit margins than those available with OE parts, if the quality of their products is accepted by the market. Besides, the aftermarket-parts market for Taiwan makers is much bigger than that for OE parts, which are supplied only to regional automakers."

The chairman also disagrees with many of his fellow parts makers about moving production to mainland China. "Most of our rivals in Taiwan have set up facilities on the other side of the Taiwan Strait in a bid to win OE orders from automakers there," he comments, "but we have no such intention at this time. Furthermore, the quality of upstream materials in the mainland is still too unstable to assure product quality, and that is precisely where our competitive edge lies."

Lee goes on to point out that the market for aftermarket-parts sales in the mainland is still too small to support the capacity of a large plant there, and this is another reason why he has decided to keep his operations in Taiwan for the time being.

Local manufacturers in the line point out that more car owners than ever are now willing to use non-OE parts in their repairs. Statistics compiled by the Insurance Research Committee (IRC) of the U.S. show that the acceptance ratio for such parts in that country now stands at 52%, more than double the 2000 figure of 25%.

An even higher 57% of American consumers are willing to use such parts if they bear marks showing ISO9000, Certified Automotive Parts Association (CAPA), or Manufacturers' Qualification and Validation Program (MQVP) quality approval. This indicates that non-OE parts have become the mainstay of the aftermarket in North America.

OE replacement parts are often distributed through auto manufacturers' own service channels and sold under their own brands, while non-OE aftermarket parts, which have the same specifications as their OE counterparts, are often sold without certification or authorization by the automakers.

Several major producers in Taiwan predict that sales of their aftermarket auto parts will expand by about 20% annually in 2003 and the next several years, due largely to the fact that the number of older cars on the world's streets and highways is growing rapidly because of the weak global economy and the improved durability of late-model cars.

Reflecting the change in consumer habits as well as cost concerns (aftermarket parts cost only about 60% to 80% as much as OE counterparts), more and more insurance companies are using the prices of aftermarket parts in calculating compensation payouts. Farmers and Nationwide, the third- and fourth-largest U.S. insurance firms, have already taken this action, and State Farm, the biggest, is expected to shortly follow suit. This is expected to help boost the American market for aftermarket parts by 20% to 40% this year.

The acceptance of aftermarket parts is also benefiting from the differential-premium system offered by American insurance firms, which allows policyholders to pay lower premiums if they agree to the use of aftermarket parts to repair their cars.

Expanding Production

In response to the burgeoning market, local manufacturers are expanding their production both in Taiwan and overseas. They are also diversifying their product lines with the aim of attracting more one-stop shoppers.

One example of this trend is provided by Gordon Auto Body Parts Co., a leading local supplier of aftermarket sheet-metal body parts, which claims that it has invested over NT$100 million (US$2.9 million at NT$34.8:US$1) to expand production at its second Taiwan plant by installing two new stamping lines. When this project is completed in the second quarter of this year, it will give the company an annual capacity of 1.5 million sheet-metal parts.

Gordon also says that it spends an average of NT$400 million to NT$500 million (US$11.5-14.4 million) a year on die development. It plans to develop 50 additional dies this year, bringing the total to over 500.

The company's chairman, Lee Mao-yuan, is highly confident in his firm's prospects. "We expect to lengthen our lead over our major domestic rivals this year," he explains, "thanks to our expanded production capacity, our new dies, and the flood of orders coming in from our customers—especially those in the U.S. market."

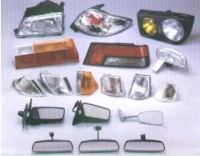

Taiwan`s aftermarket auto parts are known for high quality and low price. (photo courtesty of Patmax Union Corp.)

The other factor, Lee explains, is the reduction of Gordon's production costs because booming demand has heightened its die-utilization ratio. Also, of course, the company is expected to end its long-term capacity shortage through the above-mentioned expansion at its second Taiwan plant as well as through the strengthening of cooperative ties with satellite plants.

Advantage of Experience

In the face of rising competition from a group of newcomers to the line, Lee comments, Gordon's competitive edge lies mainly in its long-term manufacturing experience and its dedication to the continual development of more advanced production technology. "This is why our company has been able to stand firm amidst the bloody competition in the past," he explains.

In addition, Lee says, the company's strategy of developing comprehensive die series instead of one-offs makes it an ideal supplier of one-stop-shopping services.

Gordon is not going the way of many other auto-parts makers, who according to Lee aim at becoming OE suppliers because of the higher profit margins this makes possible. In fact, he explains, "Aftermarket-parts makers can use much more flexible pricing strategies or tactics and gain even better profit margins than those available with OE parts, if the quality of their products is accepted by the market. Besides, the aftermarket-parts market for Taiwan makers is much bigger than that for OE parts, which are supplied only to regional automakers."

The chairman also disagrees with many of his fellow parts makers about moving production to mainland China. "Most of our rivals in Taiwan have set up facilities on the other side of the Taiwan Strait in a bid to win OE orders from automakers there," he comments, "but we have no such intention at this time. Furthermore, the quality of upstream materials in the mainland is still too unstable to assure product quality, and that is precisely where our competitive edge lies."

Lee goes on to point out that the market for aftermarket-parts sales in the mainland is still too small to support the capacity of a large plant there, and this is another reason why he has decided to keep his operations in Taiwan for the time being.

©1995-2006 Copyright China Economic News Service All Rights Reserved.