Outdoor & Public-Area Furniture Taiwanese Makers Move Up and Out

Mar 24, 2006 Ι Industry News Ι Furniture Ι By Ben, CENS

Although many Taiwanese manufacturers of outdoor and public-area furniture have already moved production facilities to mainland China and Vietnam over the past several years, some have stayed rooted in Taiwan and are upgrading their manufacturing skills and capacity to penetrate the upscale marketplace. One such producer in Taiwan claims that many domestic manufacturers have successfully adopted advanced manufacturing and surface treatment technologies to roll out environmentally-friendly products.

A domestic manufacturer in this line notes Taiwan is still a good place to produce high-end outdoor and public-area furniture because of the ample supply of high-end parts and a huge pool of skilled workers. But he also warns that furniture manufacturers in the mainland are elevating product quality to grab a bigger slice of the high-end furniture market.

Taiwanese manufacturers of outdoor and public-area furniture say more of their foreign customers are demanding high-quality furniture made in the mainland, a trend that is encouraging mainland producers to tilt production towards higher-end products.

To meet the demand of foreign customers, some Taiwanese producers of outdoor and public-area furniture with production facilities in the mainland are taking steps to reduce the ratio of product defects by streamlining management and production procedures. The race to expand capacity, a focal point in earlier years, has faded as producers shift attention from quantity to quality.

Avoiding the Crush

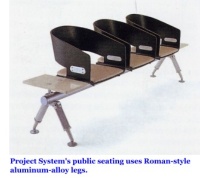

To avoid harsh competition in the mass-produced furniture market, Project Systems Furniture Co. began developing high-end system furniture made of aluminum alloy four years ago. The new furniture has a wide range of public applications and they are made of recyclable materials.

The company claims it has extensive expertise in developing furniture items made with unique mechanical structures.

Project Systems currently specializes in the production of aluminum-alloy furniture with anodized surface treatment. The company says anodized aluminum-alloy furniture parts have an insulating quality and are therefore suitable for use in hospitals and semiconductor clean rooms.

The aluminum-alloy furniture developed by the company can be disassembled to meet international standards requiring furniture parts to be separately recycled by category.

The company's furniture design ability owes much to the expertise of its president Alex Lee and a design team of four talented people.

"Taiwan has too many manufacturers concentrating on wood panel furniture, " laments Lee. "To avoid intense competition resulting from too many manufacturers, we decided to focus on aluminum-alloy furniture with unique mechanical structures. As production of the aluminum-alloy furniture relies on high design skill, we have been able to operate in the domestic market without competition since our inception."

Project Systems makes both household and office furniture. Although office furniture, including executive desks, public-use chairs, and display racks, still dominates output at its production facility in Taishan of Taipei County, the company is now promoting a newly designed "Casa IO" series of household furniture.

The company says it is one of the few manufacturers of anodized furniture and parts in Taiwan. "The uniquely shaped legs on our dining tables can be applied to other kinds of furniture items, such as computer desks, conference tables and occasional tables, " says Lee.

Lee says the anodized aluminum-alloy legs of the "Casa IO" series of dining tables have a steady structure with no welding spot. The leg also can be extended for use with tabletops of various dimensions.

The company says it can deliver dining sets or legs only. Lee notes that global demand for household furniture items made of aluminum alloy is on the rise. "In the past, most household consumers preferred furniture items made of wood, glass and fabric. Nowadays more and more consumers accept items made of aluminum alloy because of their unique styles and designs, " says Lee.

Lee says he has licensed a Taiwanese-invested firm in the mainland to produce furniture on a royalty basis.

Project Systems won the iF design award.CHINA sponsored by Hanover Fairs China Ltd. In Shanghai, mainland China in September 2003 for its "A-Plus" series of furniture. The "A-Plus" series also won the silver medal at the11th ROC National Award of Excellence competition activity in 2004.

The iF design award, created by Germany's Hanover Fairs International Co., has a history of a half century. The iF design award.CHINA is targeted at manufacturers and designers who are active in the Chinese marketplace.

Project says the "A-Plus" series helps consumers organize conference areas in a dynamic, versatile and innovative way. The Arc-curved and asymmetrical tables in the series can be arranged freely to create different configurations, he says.

Lee boasts that his company is continually adding to the "A-Plus" series to suit the diverse needs of the modern office, from executive suites to multiple and individual workstations, conference rooms, and reception areas, as well as for use in professional studios and home offices.

Public Seating

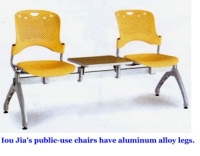

A veteran manufacturer of office chairs, Iou Jia Industrial Co., Ltd., established about two decades ago, has been rolling out public-area chairs for three years. Company president Lin Yu-jen notes his company is gearing up to develop a wider range of furniture products to meet the demand of foreign customers.

Lin says his company has extensive expertise in making high-end office and public-area chairs, and it has made a significant investment in production molds for such items. "The cost of making molds for public-area chairs is so high that few others bother to copy us, " says Lin. "We can develop new types of public-area chairs so quickly that our rivals can't keep up."

Over the past three years, the company has remodeled some of its public-area chairs several times to enhance their functionality. For instance, such chairs can be applied to conference rooms, employee education and training centers, hospitals and the waiting rooms of air terminals.

"We don't make a large quantity for each model of the public-area chairs, " notes Sophia Chen, export manager of the company. "Public-area chairs are generally made to meet specific case-by-case needs."

Chen says her company focuses on the development of high-end office and public-area furniture, most of which are made of injected plastic and aluminum alloy parts that the company claims are of higher quality than those made in the mainland.

"Our chair bases are made of aluminum alloy which is rust-proof and more steady than bases made of iron pipes, " notes Chen. "Although we just began developing public-area chairs only three years ago, this product accounts for 30% of our total output and the ratio is expected to increase in the years to come."

In addition to developing brand-new high-end public-area chairs, the company has introduced several types of office chairs to its line over the past few years,

The company's newly developed chair models of LM-2686AX, LM-2687AX and LM-9988AX have an aluminum base enveloped in a plastic casing. The unit is built with several molds costing upwards of NT$1 million (US$31, 200) each to make, Chen claims.

All three models have pneumatic bars underneath the seats to adjust the height as well as a device that enables the seat to tilt backward synchronously with the back support.

The LM-9988AX, which features a height-adjustable headrest, is designed for both corporate executives and SOHO (small office, home office) workers. The other two models are intended primarily for use by general office workers.

Chen notes that with mainland Chinese and Malaysian manufacturers eroding Taiwan's market share in the Middle East and the U.S. in the middle and lower ranges, manufacturers that keep production on the island have to roll out new products very quickly in order to keep ahead of the competition.

Quality, Chen thinks, is another advantage that Taiwanese manufacturers have over their mainland rivals. Over the past few years, Iou Jia has earned ISO9001 and Taiwan's Chinese National Standard (CNS) certifications, helping the company tap both export orders and domestic government contracts. The company currently mainly exports products to the Middle East, mainland China, Japan, Southeast Asia, Europe, and Latin America.

In addition to making public-area chairs, Iou Jia also supplies unassembled plastic seats for export. "The unassembled seats reduce shipping space and cost, " explains Chen. "More and more foreign furniture manufacturers are asking us to ship plastic seats because they have confidence in our ability to develop sophisticated molds for such items."

Value from Vietnam

Yu Sern Furniture Industrial Co., Ltd., established 15 years ago, is one of Taiwan's leading manufacturers of outdoor furniture made of wood and iron. In order to make price-competitive products in large quantities, the company set up an affiliate in Vietnam eight years ago and has since moved its production facilities there.

Today the company operates three production facilities in Vietnam and it plans to keep expanding there. In addition to boosting production capacity, the company has also focused on the implementation of strict quality-control procedures and the adoption of advanced production methods.

"We have accumulated a lot of expertise in producing outdoor furniture made with high-quality materials, " says Lu Chin-fu, president of the company. "Our relocation to Vietnam is aimed at boosting production capacity, rather than cutting production costs. The combination of our expertise and Vietnam's huge pool of workers has ensured us a successful business model."

The company says its furniture items are made of high-quality spruce imported from abroad, mainly the U.S. and Canada. All of the company's products are exported. Major export outlets include the U.S., Canada, and Western Europe.

In addition to outdoor furniture, Yu Sern also produces several indoor items, including desks, chairs and sofas.

"Most of our products are made on an original equipment manufacturer (OEM) basis and are patented, " says Lu. "The majority of our customers are in upscale markets. We have ensured our customers that their patented products won't be sold to others so as their rights can be fully protected."

Quality King

King Hong Industrial Co., established in 1976, is a specialist manufacturer of office chairs. The company turns out its high-quality products at an integrated production facility in Kaohsiung of southern Taiwan.

The company's product development focuses on user- and environmentally-friendly designs. The company also can develop sophisticated molds for the production of high-quality steel parts and plastics used in its chair ranges.

Apart from its innovative designs, the company has paid much attention to meeting high standards of on-time delivery.

King Hong's extensive product line currently includes office, leather, swivel, and visitor chairs. In the second half of last year, the company added public-area chairs to its product range.

King Hong says it only focuses on the production of high-quality outdoor and public-area chairs. The mechanisms, pneumatic cylinders, plywood, plastic parts, bases and casters used on these chairs are covered by a two-year warranty.

The ISO-9001-certified company says its products meet the U.S. BIFMA and Japanese JIS standards.

Iron and Aluminum Alloy Specialist

Another manufacturer of outdoor furniture with production facility in mainland is Jiann Shing Hardware Co., which was established two decades ago. The company supplies a wide range of indoor and outdoor furniture made of iron and aluminum alloys.

Jiann Shing moved its production facilities to Shenzhen in Guangdong Province, mainland China approximately 14 years ago to reduce production costs.

The company moved to the mainland along with a Taiwan-based trading company specializing in sourcing high-quality foreign-made materials, including iron, steel, and aluminum alloy. With the assistance of the specialist trader, Jiann Shing boasts it can source high-quality materials at preferential prices so as to keep costs down.

After relocating production to the mainland, the company shut down its Taiwan's production lines, keeping only an office on the island to handle financial and administration operations.

The company's outdoor items include greenhouses and tents. Its indoor furniture items include chairs, computer desks, television shelves and storage racks.

The company's Shenzhen plant has 600 workers under a Taiwanese management team.

"We have seen fast revenue growth and made several plant expansions since our relocation to the mainland, " says Liang Tsun-hsiao, president of the company. "In the next two or three years, we will focus on streamlining production, rather than production expansion, in a bid to elevate the value of our products."

Liang says seeking cheaper production costs in the mainland is no longer an advantageous factor for domestic furniture manufacturers who want to relocate their production facilities there. "Foreign buyers have increasingly demanded that mainland furniture producers provide high-quality products in sizeable quantities, " says Liang. "So we have to concentrate on reducing defect ratios by streamlining management and production procedures."

In the near future, the company will adopt some necessary steps to standardize its production procedures so as to enhance product quality.

The company says it sells products to many hypermarkets and supermarkets around the world through foreign importers and domestic traders. In recent years, the company has recruited some export specialists to handle its export business.

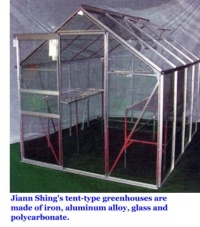

Jiann Shing's tent-type greenhouses are made of iron, aluminum alloy, glass and polycarbonate. All such products are designed by the company.

The tent-type greenhouse has been one of the company's hottest selling products over the past years. The greenhouses are made of environmentally-friendly polyethylene fabric, " says Liang. "In the near future, we will continuously develop more items that are earth friendly."

Currently Jiann Shing exports most of its products to Europe, the U.S. and Japan, with Europe taking over 70% of the export total. The company set up a marketing office in the U.S. in the second half of 2005 to expand sales there.

Over the past several years, the company has enjoyed double-digit annual sales growth, including a 25% revenue gain in 2005. It expects to grow even faster in 2006.

The company regularly participates in international exhibitions, including major furniture shows in Chicago, USA and Cologne, Germany.

A domestic manufacturer in this line notes Taiwan is still a good place to produce high-end outdoor and public-area furniture because of the ample supply of high-end parts and a huge pool of skilled workers. But he also warns that furniture manufacturers in the mainland are elevating product quality to grab a bigger slice of the high-end furniture market.

Taiwanese manufacturers of outdoor and public-area furniture say more of their foreign customers are demanding high-quality furniture made in the mainland, a trend that is encouraging mainland producers to tilt production towards higher-end products.

To meet the demand of foreign customers, some Taiwanese producers of outdoor and public-area furniture with production facilities in the mainland are taking steps to reduce the ratio of product defects by streamlining management and production procedures. The race to expand capacity, a focal point in earlier years, has faded as producers shift attention from quantity to quality.

Avoiding the Crush

To avoid harsh competition in the mass-produced furniture market, Project Systems Furniture Co. began developing high-end system furniture made of aluminum alloy four years ago. The new furniture has a wide range of public applications and they are made of recyclable materials.

The company claims it has extensive expertise in developing furniture items made with unique mechanical structures.

Project Systems currently specializes in the production of aluminum-alloy furniture with anodized surface treatment. The company says anodized aluminum-alloy furniture parts have an insulating quality and are therefore suitable for use in hospitals and semiconductor clean rooms.

The aluminum-alloy furniture developed by the company can be disassembled to meet international standards requiring furniture parts to be separately recycled by category.

The company's furniture design ability owes much to the expertise of its president Alex Lee and a design team of four talented people.

"Taiwan has too many manufacturers concentrating on wood panel furniture, " laments Lee. "To avoid intense competition resulting from too many manufacturers, we decided to focus on aluminum-alloy furniture with unique mechanical structures. As production of the aluminum-alloy furniture relies on high design skill, we have been able to operate in the domestic market without competition since our inception."

Project Systems makes both household and office furniture. Although office furniture, including executive desks, public-use chairs, and display racks, still dominates output at its production facility in Taishan of Taipei County, the company is now promoting a newly designed "Casa IO" series of household furniture.

The company says it is one of the few manufacturers of anodized furniture and parts in Taiwan. "The uniquely shaped legs on our dining tables can be applied to other kinds of furniture items, such as computer desks, conference tables and occasional tables, " says Lee.

Lee says the anodized aluminum-alloy legs of the "Casa IO" series of dining tables have a steady structure with no welding spot. The leg also can be extended for use with tabletops of various dimensions.

The company says it can deliver dining sets or legs only. Lee notes that global demand for household furniture items made of aluminum alloy is on the rise. "In the past, most household consumers preferred furniture items made of wood, glass and fabric. Nowadays more and more consumers accept items made of aluminum alloy because of their unique styles and designs, " says Lee.

Lee says he has licensed a Taiwanese-invested firm in the mainland to produce furniture on a royalty basis.

Project Systems won the iF design award.CHINA sponsored by Hanover Fairs China Ltd. In Shanghai, mainland China in September 2003 for its "A-Plus" series of furniture. The "A-Plus" series also won the silver medal at the11th ROC National Award of Excellence competition activity in 2004.

The iF design award, created by Germany's Hanover Fairs International Co., has a history of a half century. The iF design award.CHINA is targeted at manufacturers and designers who are active in the Chinese marketplace.

Project says the "A-Plus" series helps consumers organize conference areas in a dynamic, versatile and innovative way. The Arc-curved and asymmetrical tables in the series can be arranged freely to create different configurations, he says.

Lee boasts that his company is continually adding to the "A-Plus" series to suit the diverse needs of the modern office, from executive suites to multiple and individual workstations, conference rooms, and reception areas, as well as for use in professional studios and home offices.

Public Seating

A veteran manufacturer of office chairs, Iou Jia Industrial Co., Ltd., established about two decades ago, has been rolling out public-area chairs for three years. Company president Lin Yu-jen notes his company is gearing up to develop a wider range of furniture products to meet the demand of foreign customers.

Lin says his company has extensive expertise in making high-end office and public-area chairs, and it has made a significant investment in production molds for such items. "The cost of making molds for public-area chairs is so high that few others bother to copy us, " says Lin. "We can develop new types of public-area chairs so quickly that our rivals can't keep up."

Over the past three years, the company has remodeled some of its public-area chairs several times to enhance their functionality. For instance, such chairs can be applied to conference rooms, employee education and training centers, hospitals and the waiting rooms of air terminals.

"We don't make a large quantity for each model of the public-area chairs, " notes Sophia Chen, export manager of the company. "Public-area chairs are generally made to meet specific case-by-case needs."

Chen says her company focuses on the development of high-end office and public-area furniture, most of which are made of injected plastic and aluminum alloy parts that the company claims are of higher quality than those made in the mainland.

"Our chair bases are made of aluminum alloy which is rust-proof and more steady than bases made of iron pipes, " notes Chen. "Although we just began developing public-area chairs only three years ago, this product accounts for 30% of our total output and the ratio is expected to increase in the years to come."

In addition to developing brand-new high-end public-area chairs, the company has introduced several types of office chairs to its line over the past few years,

The company's newly developed chair models of LM-2686AX, LM-2687AX and LM-9988AX have an aluminum base enveloped in a plastic casing. The unit is built with several molds costing upwards of NT$1 million (US$31, 200) each to make, Chen claims.

All three models have pneumatic bars underneath the seats to adjust the height as well as a device that enables the seat to tilt backward synchronously with the back support.

The LM-9988AX, which features a height-adjustable headrest, is designed for both corporate executives and SOHO (small office, home office) workers. The other two models are intended primarily for use by general office workers.

Chen notes that with mainland Chinese and Malaysian manufacturers eroding Taiwan's market share in the Middle East and the U.S. in the middle and lower ranges, manufacturers that keep production on the island have to roll out new products very quickly in order to keep ahead of the competition.

Quality, Chen thinks, is another advantage that Taiwanese manufacturers have over their mainland rivals. Over the past few years, Iou Jia has earned ISO9001 and Taiwan's Chinese National Standard (CNS) certifications, helping the company tap both export orders and domestic government contracts. The company currently mainly exports products to the Middle East, mainland China, Japan, Southeast Asia, Europe, and Latin America.

In addition to making public-area chairs, Iou Jia also supplies unassembled plastic seats for export. "The unassembled seats reduce shipping space and cost, " explains Chen. "More and more foreign furniture manufacturers are asking us to ship plastic seats because they have confidence in our ability to develop sophisticated molds for such items."

Value from Vietnam

Yu Sern Furniture Industrial Co., Ltd., established 15 years ago, is one of Taiwan's leading manufacturers of outdoor furniture made of wood and iron. In order to make price-competitive products in large quantities, the company set up an affiliate in Vietnam eight years ago and has since moved its production facilities there.

Today the company operates three production facilities in Vietnam and it plans to keep expanding there. In addition to boosting production capacity, the company has also focused on the implementation of strict quality-control procedures and the adoption of advanced production methods.

"We have accumulated a lot of expertise in producing outdoor furniture made with high-quality materials, " says Lu Chin-fu, president of the company. "Our relocation to Vietnam is aimed at boosting production capacity, rather than cutting production costs. The combination of our expertise and Vietnam's huge pool of workers has ensured us a successful business model."

The company says its furniture items are made of high-quality spruce imported from abroad, mainly the U.S. and Canada. All of the company's products are exported. Major export outlets include the U.S., Canada, and Western Europe.

In addition to outdoor furniture, Yu Sern also produces several indoor items, including desks, chairs and sofas.

"Most of our products are made on an original equipment manufacturer (OEM) basis and are patented, " says Lu. "The majority of our customers are in upscale markets. We have ensured our customers that their patented products won't be sold to others so as their rights can be fully protected."

Quality King

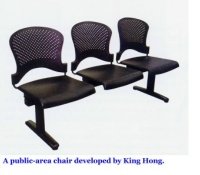

King Hong Industrial Co., established in 1976, is a specialist manufacturer of office chairs. The company turns out its high-quality products at an integrated production facility in Kaohsiung of southern Taiwan.

The company's product development focuses on user- and environmentally-friendly designs. The company also can develop sophisticated molds for the production of high-quality steel parts and plastics used in its chair ranges.

Apart from its innovative designs, the company has paid much attention to meeting high standards of on-time delivery.

King Hong's extensive product line currently includes office, leather, swivel, and visitor chairs. In the second half of last year, the company added public-area chairs to its product range.

King Hong says it only focuses on the production of high-quality outdoor and public-area chairs. The mechanisms, pneumatic cylinders, plywood, plastic parts, bases and casters used on these chairs are covered by a two-year warranty.

The ISO-9001-certified company says its products meet the U.S. BIFMA and Japanese JIS standards.

Iron and Aluminum Alloy Specialist

Another manufacturer of outdoor furniture with production facility in mainland is Jiann Shing Hardware Co., which was established two decades ago. The company supplies a wide range of indoor and outdoor furniture made of iron and aluminum alloys.

Jiann Shing moved its production facilities to Shenzhen in Guangdong Province, mainland China approximately 14 years ago to reduce production costs.

The company moved to the mainland along with a Taiwan-based trading company specializing in sourcing high-quality foreign-made materials, including iron, steel, and aluminum alloy. With the assistance of the specialist trader, Jiann Shing boasts it can source high-quality materials at preferential prices so as to keep costs down.

After relocating production to the mainland, the company shut down its Taiwan's production lines, keeping only an office on the island to handle financial and administration operations.

The company's outdoor items include greenhouses and tents. Its indoor furniture items include chairs, computer desks, television shelves and storage racks.

The company's Shenzhen plant has 600 workers under a Taiwanese management team.

"We have seen fast revenue growth and made several plant expansions since our relocation to the mainland, " says Liang Tsun-hsiao, president of the company. "In the next two or three years, we will focus on streamlining production, rather than production expansion, in a bid to elevate the value of our products."

Liang says seeking cheaper production costs in the mainland is no longer an advantageous factor for domestic furniture manufacturers who want to relocate their production facilities there. "Foreign buyers have increasingly demanded that mainland furniture producers provide high-quality products in sizeable quantities, " says Liang. "So we have to concentrate on reducing defect ratios by streamlining management and production procedures."

In the near future, the company will adopt some necessary steps to standardize its production procedures so as to enhance product quality.

The company says it sells products to many hypermarkets and supermarkets around the world through foreign importers and domestic traders. In recent years, the company has recruited some export specialists to handle its export business.

Jiann Shing's tent-type greenhouses are made of iron, aluminum alloy, glass and polycarbonate. All such products are designed by the company.

The tent-type greenhouse has been one of the company's hottest selling products over the past years. The greenhouses are made of environmentally-friendly polyethylene fabric, " says Liang. "In the near future, we will continuously develop more items that are earth friendly."

Currently Jiann Shing exports most of its products to Europe, the U.S. and Japan, with Europe taking over 70% of the export total. The company set up a marketing office in the U.S. in the second half of 2005 to expand sales there.

Over the past several years, the company has enjoyed double-digit annual sales growth, including a 25% revenue gain in 2005. It expects to grow even faster in 2006.

The company regularly participates in international exhibitions, including major furniture shows in Chicago, USA and Cologne, Germany.

©1995-2006 Copyright China Economic News Service All Rights Reserved.